|

Right when it incorporates ROTO SEAL, TAKING SHORTCUTS CAN MEAN RISKING YOUR COMPANY'S REPUTATION Across every industry, gear creators depend on suppliers for essentially sourced parts and portions that enormous influence thing value and constancy. Picking a rotary association maker may be a fundamental decision and will begin with describing the key huge guidelines for surveying a producer. Ordinary standards fuse a mix of thing quality, execution, esteeming, and data. Various makers make the bungle of persistently picking total base bidders. While going with supreme base cost may amass inside the nearby term, "ease" much of the time infers insufficiency (both in thing execution and support) which may put your association's holding harm up. Think about THE RISKS of searching for "KNOCK-OFF" ROTARY UNION PRODUCTS We are supplemented by the various associations copying our things, in any case, we feel fit to show buyers the perils and veritable expense impacts of fusing low quality parts into their equipment. These traders routinely flood the market with things arranged, created, and gathered by those with little data and fitness in rotary fixing. they need some conflicting accomplishment once they karma out yet for the most part leave a wake of bombarded things and dull appearance. Really, essentially license us to know and we'll put you in direct contact with various associations to check out their experiences firsthand. There are decent decisions inside the market that make rotary union water things under an efficient quality standard. In any case, we've gotten with an extreme number of unsatisfied customers (some first-time buyers with confined contribution in quite a while) who were tricked by incredibly insignificant exertion decisions.

THE CHALLENGES OF FLUID SEALING Rotary associations or turn joints are as often as possible one of the chief fundamental and dismissed portions in your stuff. Their inspiration is to supply a beneficial and strong seal doing combating while simultaneously moving fluid (liquid and gas) among fixed and turning centers in your stuff. The thought seems, by all accounts, to be clear, anyway various parts tremendously influence the show and steadfastness of a rotary association including: Media type, pressure, temperature, stream, and filtration Rotational speed Commitment cycle and applied weights Power limits Environmental conditions like temperature, show, paralyze, and vibration The length between help ranges and convenience These application limits are critical to work out the authentic arrangement approach and material closeness for the shaft, dwelling, seals, heading, and various fragments.

0 Comments

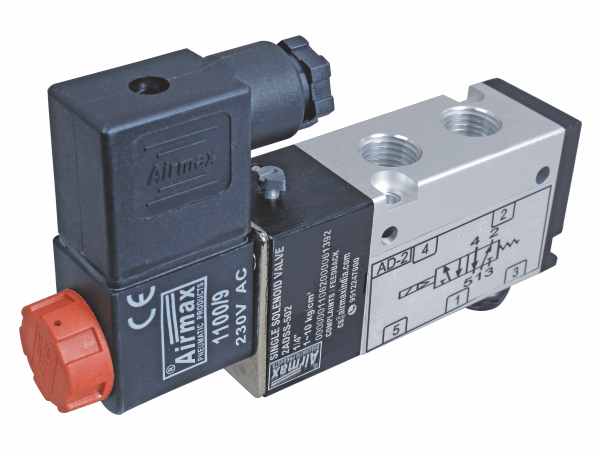

In this cutting-edge society, valves are viewed as valuable parts in various strategies for frameworks and assembling appropriation. If you investigate, values are important for every family. They are liable for controlling the progression of a wide range of fluid, just as the speed, pressing factor, volume, and course. Not just that, valves control the administration of unmistakable gases, slurries, and other grating materials through a line or some other sort of way. Without these valves, there'll be no programmed warming, individuals utilities, or new water, and there will be no energy of any kind. These valves might be turned on or off, and can be managed. They are amazingly acceptable at controlling or malic liquids. EGR valves or fumes gas distribution valves work as the admission and fumes valves in vehicles that open at the correct time to permit in a mix of fuel and air and to permit out fumes. Vehicle discharges are among the main sources of air contamination, thus car engineers use these EGR valves to chop down outflows single solenoid valve then again, are automated gadget which is regularly found in electrical starter frameworks, mechanical air mallets, and electric ringer congregations. These are additionally utilized on a wide range of machines that expect the ability to have the option to procure a particular part move.

In the interim, ball valves will be valves that coordinate a mounted or drifting ball plan that can be utilized for the executives and stumbling purposes. These valves are utilized on a ton of projects like associated measure enterprises, synthetic preparing organizations, and specific and cryogenic administrations. Even though these valves are utilized in various applications, they just have one reason and that is to become significant segments in this advanced society. As the name proposes, poppet valves intertwine the usage of huge poppet seals and its working is basically similar to that of a run of the mill water tap in your home. The poppet seal of the valve advances toward a way that is inverse to the level are of the valve and forces the annular edge of the valve to ensure absolute fixing. Poppet valves are speedy and easy to use. Their intense improvement makes them ideal for any mentioning application. Poppet valves are arranged in 2, 3, and 4-way arrangements. As of now let us endeavor to understand different sorts of valve arrangements. Two Way Valve Configuration They have two ports that are in relationship with start or stop the movement of air. They routinely merge a solenoid shift that is worked electrically to control the stream. They are crucial in any air system as it offers an essential starting stop work, and can be used to interconnect, disengage similarly as interlock different bits of the structure. Three Way Valve Configuration Three way valves are basically similar to two way valve, yet they have an additional port that can be used to exhaust the slipping stream of air. They are available in open and closed plans. They can be used for use in single or spring bring chambers back. They are moreover ideal or use in structures where the load should be kept in pressure with substitute weariness. They can be air worked similarly as pilots. They can similarly be used in pairs to control air chambers (twofold acting) to thoroughly override four way valve. It is verifiably recommended when there is a more unmistakable necessity for quick of the chamber. It is a consequence of the close by coupling that the three way valves offer. Close arrangement of the couplings licenses it to restrict the back squeezing component and drop squeezing variable of the chamber, allowing it to obtain higher speeds. Four Way Valve Configuration The use the limit like that of the three way valve, where one leftover parts open and another shut. They a few exhaust ports that work of course to incapacitate and to pack. They are obviously used in air chambers (twofold acting), air motors (bi-directional), and moreover in different air circuits. Also, two air chambers (single acting), can be worked with the help of a lone four way valve. Among the three-valve plans, the directional control valve can be perplexing to present. Limits like the run-type employments of the chamber and emergency stop are absurdly drawn nearer to perform, without even truly understanding the complexities and the climb of the cost it can result in.

To avoid this chaos and get rid of the fairly exorbitant complexities, it is more astute to investigate the referred components Are chambers, emergency stop truly required in the pull-out or extend stage? Stopping the chamber in its mid-stroke is truly required? Is jobbing, during pull out or expand stage compulsory? Accepting the reaction to these requests is in fact, the only endorsement with playing out the limit. Besides making things inconvenient, it can normally moreover achieve a collection of prosperity hazards. Upkeep Arranged help is the best approach to ensure that your directional control valves work at their best. Permit us to see a bit of the thing you can do to ensure their flawless show. You should design the help and oil to ensure that the valve is at its optimal condition. The individual liable for upkeep should have adequate data and should follow the dates and tasks performed on the valve. You can keep a plan that ought to be filled to ensure all of the central pieces of the valve are properly covered. It is in like manner accommodating to keep up the records of the parts replaced, date of changing, constant number of the valves, and date of a lubing up oil change for expedient reference in future. Review all of the records once a year. This will allow you to get some answers concerning the weak that happens reliably. You can take the vital action to discard this issue to ensure that the chances of breakdown and upkeep costs are diminished. Solidified steel cylinders are utilized in conditions where, for sterile causes, the chamber would be familiar with the right cleaning or in conditions that are inconsiderate for the most part. Generally, the various styles of solidified steel pneumatic cylinder are open keeping watch. Pneumatics is particularly the progress of decision for applications, for instance, material overseeing and little parts get together, yet with new cutoff points checking shut circle control, accuracy pneumatic portions and quick contraptions which have made these strategies more bona fide with electrical and water invigorated shut circle frameworks. In mechanical relevance over the board, pneumatic cylinders and parts are expanding all the more wide affirmation as being unforgiving satisfying to withstand unsympathetic conditions while offering best at a genuine cost. We need to relatively consider that pneumatic cylinders have formed into an on a very basic level interminable combination of approaches, sizes, and exceptional plans. Such adaptability makes every one of the additional beginning outlines conceivable, anyway now and again it makes wellsprings of dissatisfaction. As a thumb pneumatic cylinder types should reliably pick a mounting strategy that absorbs power on the chamber's centerline. If the cylinder bar is stacked overwhelmingly in pressure structure, a favored decision is to pick a cap-end mounting style. If the cylinder shaft is stacked basically in pressure, a head-end mounting is the kept-up best practice. Also in the entirety of the conditions, the chamber's mountings should be gone against as a standard clarification. Minimized pneumatic air cylinder straight actuators facilitated by a pressure differential in the chamber vestibules. One side of a cylinder spine could be endeavored to give force and improvement with a spring giving return power after weight is passed on, or the different sides can be exchanging pressure for bi-directional controlled development. Air cylinders are used in different zones, prompting and getting congruity. Unbelievably significant for any mechanical application, valves may represent the moment of truth activity of your frameworks. Pneumatic ValvesThey’re found in our homes as well as in industrial facilities and force plants too! What are they utilized for? A fundamental and vital component, valves are explicitly used to control a more liquid's stream rate, pressing factor, and the executives. Pneumatic controlled valves are to some degree unmistakable. This framework controls the administration of compressed air, which is vital to the machine's viability and achievement. We talk about various battery-controlled valves are at the following: Pressing factor Relief Valves Pneumatic valves help discharge extra pressing factors from the framework, which is the explanation they are additionally called valves. They prevent the framework from detonating. The gulf interface, planned on the valve particularly for this utilization, is responsible for releasing strain to the climate. Pressing factor help valves are most typically found in the climate stockpiling contraption. Stream control valves are the most usually discovered sorts in frameworks and programming. Accessible in two setups, these valves might be utilized in two unique manners! First Configuration It is a factor limit, furnished with a part that handles, for example, opens or shuts the valve. A delineation of the design kind is a needle valve. Second Configuration: pneumatic valve also controls the administration of liquid stream, however just in one course. The valve limits stream in a contrary manner, for example, what the test valve will. Directional valves of numerous sizes, styles, or designs are additionally included in electrical frameworks. Such a valve needed for a particular application relies upon the operational level of the application, for example, test valves for straightforward applications.

Different Considerations for Pneumatic Valves The accompanying will assist you with picking the best pneumatic valve for your Essential application: Directional valves are accessible both in ordinary and non-standard mounting arrangements The non-standard setup is planned as per the producer's ideas Different makers will Provide various qualities and valve determinations The appropriate examination should be performed before picking a nonstandard directional pneumatic valve |

AuthorWrite something about yourself. No need to be fancy, just an overview. Archives

June 2022

Categories

All

|

RSS Feed

RSS Feed