|

As the name proposes, poppet valves intertwine the usage of huge poppet seals and its working is basically similar to that of a run of the mill water tap in your home. The poppet seal of the valve advances toward a way that is inverse to the level are of the valve and forces the annular edge of the valve to ensure absolute fixing. Poppet valves are speedy and easy to use. Their intense improvement makes them ideal for any mentioning application. Poppet valves are arranged in 2, 3, and 4-way arrangements. As of now let us endeavor to understand different sorts of valve arrangements. Two Way Valve Configuration They have two ports that are in relationship with start or stop the movement of air. They routinely merge a solenoid shift that is worked electrically to control the stream. They are crucial in any air system as it offers an essential starting stop work, and can be used to interconnect, disengage similarly as interlock different bits of the structure. Three Way Valve Configuration Three way valves are basically similar to two way valve, yet they have an additional port that can be used to exhaust the slipping stream of air. They are available in open and closed plans. They can be used for use in single or spring bring chambers back. They are moreover ideal or use in structures where the load should be kept in pressure with substitute weariness. They can be air worked similarly as pilots. They can similarly be used in pairs to control air chambers (twofold acting) to thoroughly override four way valve. It is verifiably recommended when there is a more unmistakable necessity for quick of the chamber. It is a consequence of the close by coupling that the three way valves offer. Close arrangement of the couplings licenses it to restrict the back squeezing component and drop squeezing variable of the chamber, allowing it to obtain higher speeds. Four Way Valve Configuration The use the limit like that of the three way valve, where one leftover parts open and another shut. They a few exhaust ports that work of course to incapacitate and to pack. They are obviously used in air chambers (twofold acting), air motors (bi-directional), and moreover in different air circuits. Also, two air chambers (single acting), can be worked with the help of a lone four way valve. Among the three-valve plans, the directional control valve can be perplexing to present. Limits like the run-type employments of the chamber and emergency stop are absurdly drawn nearer to perform, without even truly understanding the complexities and the climb of the cost it can result in.

To avoid this chaos and get rid of the fairly exorbitant complexities, it is more astute to investigate the referred components Are chambers, emergency stop truly required in the pull-out or extend stage? Stopping the chamber in its mid-stroke is truly required? Is jobbing, during pull out or expand stage compulsory? Accepting the reaction to these requests is in fact, the only endorsement with playing out the limit. Besides making things inconvenient, it can normally moreover achieve a collection of prosperity hazards. Upkeep Arranged help is the best approach to ensure that your directional control valves work at their best. Permit us to see a bit of the thing you can do to ensure their flawless show. You should design the help and oil to ensure that the valve is at its optimal condition. The individual liable for upkeep should have adequate data and should follow the dates and tasks performed on the valve. You can keep a plan that ought to be filled to ensure all of the central pieces of the valve are properly covered. It is in like manner accommodating to keep up the records of the parts replaced, date of changing, constant number of the valves, and date of a lubing up oil change for expedient reference in future. Review all of the records once a year. This will allow you to get some answers concerning the weak that happens reliably. You can take the vital action to discard this issue to ensure that the chances of breakdown and upkeep costs are diminished.

0 Comments

In any framework, valves are an essential part that controls a liquid's pressing factor, flow rate, and heading. Pneumatically controlled valves direct the flow of pressurized air which is urgent to your framework's prosperity. Although the medium flowing through the framework is liquid (equivalent to pressure driven or measure water frameworks), how control is executed contrasts from numerous points of view than with a fluid.

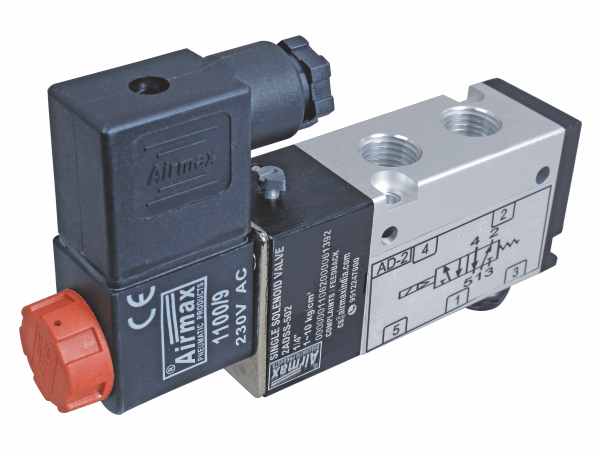

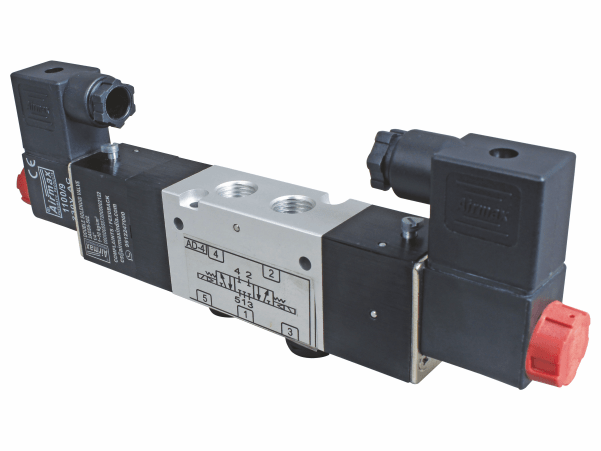

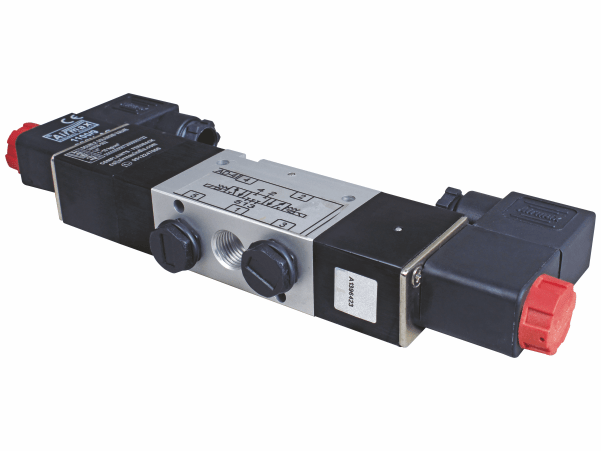

Flow Control and Directional Control Valves Valves that control flow are generally found in pneumatic frameworks. Flow control valves are accessible in two designs and are utilized in two distinct manners. The first is a variable limitation with a segment that opens or shuts the valve. This kind of valve could be known as a needle or a gag valve. The other kind is a check valve which permits flow one way, however limits flow the other way. Pneumatic frameworks can likewise highlight directional valves in numerous sizes, styles, or designs. These sorts of valves can fluctuate from a straightforward check valve to a more perplexing valve with changing positional envelopes and work ports in the valve. The directional valve includes an administrator which gives the power to move the valve between its positions. The administrator can be controlled by an assortment of instruments including a manual switch, electric solenoid, air pilot, cam system, or others. Different Considerations for Pneumatic Valves While pressure alleviation, flow control, and pneumatic directional control valve might be the most famous pneumatic valves, these valves can come in all sorts of assortments. Another regular pneumatic valve is a poppet valve that utilizes a spring to push the face of the poppet down on its seat. These valves regularly flow one way, like a check valve, however are invigorated to flow backward. Spool valves are another pneumatic valve you may go over in your inquiry. Spool valves have a scored metal chamber that slides inside a correctly machined body that is penetrated somewhere in the range of three to seven ports. At the point when you are picking your pneumatic valve, you will see that most directional valves come in both standard and non-standard mounting arrangements. The non-standard arrangement is developed at the idea of the maker. Port situating, administrator style, and mounting choices will be elite relying upon where the valve is from. Because of the irregularities among makers and their mounting inclinations, it is ideal to explore the item generally reasonable for your framework. Notwithstanding, there are additional lines of standardized valves that may suit at least one determination. In the event that your valve is specific to specific detail, it implies that one maker's valve will fit the subplate or complex of another manufacturer's. Also, port and electrical associations are standardized with most valves to help in your choice. The industrial revolution ushered in an entire new level of sector, where society has increasingly relied on innovative technology and machines to fuel economic growth and enable us to live at a level of relaxation that is unprecedented. In order to run the advanced machinery, complex processes such as radioactivity, high pressure and temperature control are required. Luckily, we have machines that can perform these sorts of tasks reliably and safely. One of the mainstays in industrial procedures are valves. They are used to control temperature, pressure, capacity and also the flow of liquids in machinery and industrial processes. Among the most useful types are solenoid valves. There is also a single solenoid valve and double solenoid valves are available. Solenoid valves make usage of electricity to control the speed and rate of fluids in a variety of types of systems and machines. Electric energy flows into a solenoid coil which leads to the creation of a magnetic field that opens a plunger to allow gas and other liquids to flow through.

Solenoids are employed in several different industries and a wide collection of processes and machines. They're employed in terminals in addition to rotary applications to control fluid power motors, cylinders and other kinds of industrial processes. Some of the major industries which use solenoids incorporate the dental health, appliance, energy, medical and transportation industries. Linear programs incorporate the use of solenoids in brakes, vending machines, door locks, copiers, coin changers, pumps, disk drive locks, film processors and electric typewriters. Rotary solenoid applications include circuit breakers, counters, defibrillators, machine tools, and textile machines. In dentist chairs they control both air and water flow. To put it differently, solenoids are part of our daily life without us even knowing it. The use of solenoids are really beneficial in a vast array of machines and industries due to their reliability, cost effectiveness and durability. There are also a number of different kinds of solenoid valves to fulfill various specific needs of industry. Solenoid valves are direct-acting or pilot-operated valves. They also come with two or more ports. Direct-acting solenoid valves are most frequently used for controlling low volume valves. This is because they contain just one electromagnetically control set. Pilot-operated valves are included in a blend of valves, which makes it possible to use them in higher volume applications. The use of solenoids offers several important benefits, especially compared with other kinds of pneumatic and hydraulic layouts. Solenoids typically operate faster and tend to be a lot easier to install in addition to maintain. Generally, solenoids also offer more constant workforce during a lengthy time period. They also offer you dependable performance. In summary, solenoids offer the advantages of longevity, reliability, speed and ease of installation and maintenance compared to other types of industrial designs. They also tend to be very reasonably priced. Solenoids are part of our daily life without us even realizing it. The simplicity of the design actually contributes to a lot of vital aspects of our lives, from the dishes we wash, java we brew and we use in our automobiles. Whether we are seeing the dentist turning to our automated sprinkler system, there is a fantastic opportunity that solenoids are operating behind the scenes to ensure the correct and safe flow of gas, water or other fluids from the machines and systems we use every day. Air blowers are frequently called a concealed utility on the grounds that relatively few individuals think about air blowers. The nearest they get to an air blower is the humming of air torques when they get their tires fitted. There is a heap of pneumatic devices accessible available today. Bureau and furniture shops utilize pneumatic nailers and staplers since nothing else looks at the speed and dependability of these instruments. Pass over firearms are the most widely recognized use for compacted air. From brushing off chips in a machine shop to improvised airbrushes, these weapons are incredibly helpful instruments. A brush off weapon is a press button valve with a release valve to center the getting away from air. This sort of weapon is favored when administrators are confined to explicit machines, for example, machines, plants, and punch presses. Pneumatic energy is directed and controlled by pneumatic valves. Practically, valves are partitioned into four significant gatherings viz, direction control, stream control, pressure control, and non-return and uncommon sort valves. According to development, valves are sub-assembled as seat valves and sliding or spool valves. Nonetheless, spool valves are simpler to make. Valves are impelled in different techniques, viz, physically, precisely, electrically, pneumatically, and by the different joined method of activation. Uncommonly planned valves like snappy fumes, time deferral, and transport and twin weight valves are utilized to grant different capacities to pneumatic circuits. To control the back and forth movement of a pneumatic chamber, the air energy should be directed, controlled, and switched with a pre-decided grouping in a pneumatic framework. Essentially, one may need to control the amount of weight and stream rate to produce the ideal degree of power and speed of actuators. To accomplish these capacities valves are utilized. Valves are liquid force components utilized for controlling and directing the working medium, i.e, the packed air on account of a pneumatic framework.

Board valves are utilized to begin and stop pneumatic energy, control the direction of the stream of compacted air, control the stream pace of packed air, and control the weight rating of the compacted air. Direction control valves are mostly used to coordinate the progression of weight liquid in the ideal direction. They can be impelled to accept various situations by different inciting mediums. This outcome in relating the association or interruption of the stream between different port openings. Direction control valves have two, three, four, or five ports or openings. In a direction control valve, the power is applied straightforwardly on the working cylinder or spool. The control strategy could be manual, mechanical, pneumatic, attractive, or a mix of any two. Magnets are usually utilized for the incitation of pneumatic valves. At the point when the magnet is energized, the unclogger gets pulled into it and it pushes down on the valve spool. The pneumatic technique follows up on a spool or cylinder with an enormous territory which thusly moves the activating power to the spool. The mechanical strategy includes the utilization of rollers, springs and other mechanical components are utilized to incite the valve. In the manual technique, the rakish development of a pedal or switch is sent to the spool. |

AuthorWrite something about yourself. No need to be fancy, just an overview. Archives

June 2022

Categories

All

|

RSS Feed

RSS Feed