|

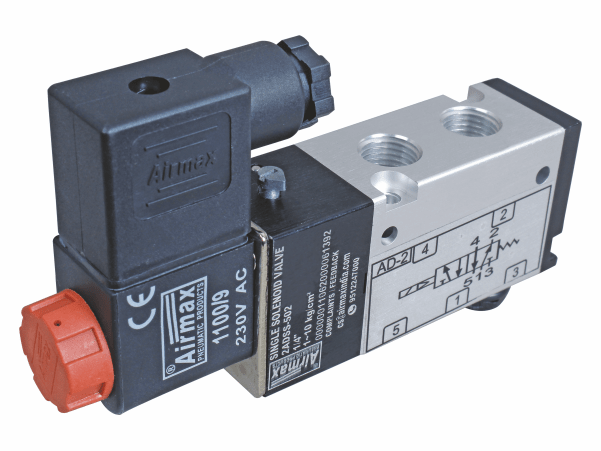

A directional control valve is a fundamental piece of strain driven and pneumatic design. It moves from an open to an absolute shut position rapidly, setting off quickly speeding up and decelerating liquid. In a water-fueled and pneumatic framework, the oil stream can be figured out how to go with directional control valve types: • Spool Type • Cartridge Type • Pilot-Operated Check Valves • Diverter type Clear Directional control valves will, all things considered, be of the diverter type and are customarily used to control the progression of water-driven and pneumatic chambers, oil entering one port and being sent on an either-or reason through two unmistakable ports or close by a tank port to the two culminations of a twofold acting chamber to develop or pull out it. The more current spool types have three positions and, ward upon the types of the spool, it will be unprejudiced in the focal position and along these lines, the two assist ports with willing either be packed or open to tank in the two interesting positions. These are generally used to stream control valve chambers with, regardless, have the piece of slack over diverters of being simpler to work under strain and can be utilized to work various chambers or potentially engines correspondingly as different actuators from the similar square of spools. Some manual spool valves will occasionally have a fourth position which is portrayed as above water and is sensibly the two help ports related so the joined water-driven and pneumatic chamber will move in and out as the store on its directions.

A pilot-worked check valve will permit oil to move uninhibitedly one way, yet it will move essentially the other way when pilot pressure is applied to take the different seats to let the hindered liquid go through. The cartridge type directional control valves work accordingly to different sorts, in any case, the valve instrument is contained inside a cartridge so it can, for instance, sired along with different kinds of cartridge valves inside a relative square.

0 Comments

What Is Pneumatic Magnet? A pneumatic magnet, additionally called an air incited magnet, is a kind of pneumatically controlled extremely durable magnet, which is typically in reduced size and with low lingering attraction. How Do Pneumatic Magnets Work? The actuation and deactivation of the magnetic field of the magnet are accomplished through a twofold acting magnetic pneumatic cylinder. Its air actuator winds down the magnet on and, permitting all the security of a long-lasting magnet that won't drop the heap during a force or air misfortune. Also, they devour fundamentally less air than vacuum grippers, in light of the fact that compacted air is utilized uniquely to turn the magnet on and off.

Provisions of Air Actuated Magnet Super durable magnets with air incitation don't change their magnetic state whenever compacted air is lost – for example, if there should be an occurrence of a harmed line or blower glitch. This component gives unwavering quality and wellbeing to material taking care of. It can likewise deal with punctured material Itcan be left "on" endlessly Simplicity of installatio |

AuthorWrite something about yourself. No need to be fancy, just an overview. Archives

June 2022

Categories

All

|

RSS Feed

RSS Feed