|

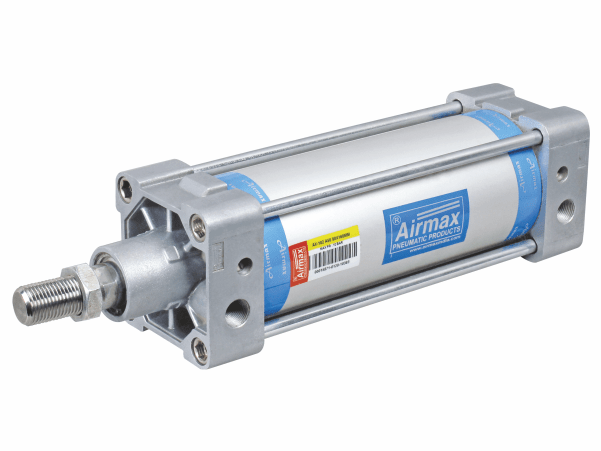

Pneumatic cylinders are the maximum frequent solution to create pressure and motion in OEM applications. The motives for this is that they may be easy in design, easy to put in, in your price range in charge, and sturdy in overall performance. Pneumatic cylinders are designed in a ramification of sizes, styles, and configurations. OEMs need to pick out the pneumatic cylinder carefully, so as to aid the application properly. The simplest way to gain that is to keep some tips in mind. The factors given underneath will help OEMs apprehend the components to recollect while deciding on pneumatic cylinders for their packages. In this submission, we can be looking at rod fashion cylinders. A round body pneumatic cylinder can be designed in two approaches – single, or double appearing. Single acting cylinders deliver compressed air to the handiest one aspect of the piston, consequently developing force and motion most effectively in one route. Double performing cylinders deliver compressed air to create sufficient force to extend in addition to retract strokes. Single performing cylinders have restricted extension due to the presence of a compressed spring within the design. The stroke period for double performing cylinders is unlimited, however the piston rod can bend or buckle after regular use over a time frame.

Pneumatic cylinder air consumption takes region due to elements. The first is the quantity of air that the piston displaces at some point of operation. The second is infected air extent that passes via the valves, ports, tubing, and end cover cavities. Customers must test whether the cylinder can supply air even in worst case situations. If the pneumatic cylinder is capable of meeting all of those criteria, then you could be certain that the cylinder will carry out well for your OEM utility.

0 Comments

It truly doesn't make any difference what kind of lifter is utilized, the general guideline is something similar, which is to communicate or pass along the development of the cam flap to the push pole. The power that exists between the lifter and the cam flap can be generally high; it additionally doesn't make any difference if the lifter is mechanical or water-driven. As the valve is being opened, remember, there should be sufficient power being applied to win over the power of the valve spring. Hence, the entirety of this power is situated on the metal-to-metal contact region associating with the cam projection and the lifter. Through the previously mentioned measure, the valves are open and shut a huge number of times each moment, and the base essence of the lifter is consistently in direct contact with the cam projection. Over the long run the entirety of this makes wear on these segments, so to decrease the measure of wear on the cam and lifter, various present-day motors currently use roller lifters. A joined form of mechanical and pressure-driven lifters is the thing that makes up a roller lifter. The actual body might be mechanical or water-powered that makes up a roller lifter, in any case, the thing that matters is in the lower part of the lifter that contacts the cam flap. A little metal wheel or roller is mounted straightforwardly to the lower part of the lifter that rides on the cam projection, as opposed to a level metal surface. The roller valve resembles a wheel caster and the activity of the wheel on the lifter is tantamount to that of an office seat. A seat without wheels has a great deal of opposition and is moderately difficult to slide across the floor.

Then again the seat will get moderately inconvenience-free across the floor with next to zero opposition when there are wheels joined, this likewise remains constant for the roller lifter. With the case of the workplace seat as a primary concern, the lifter is allowed to pivot when a roller is appended as far as possible. Hence, as the wheel rides the length of the camshaft projection, the roller fundamentally turns instead of sliding along the essence of the flap-like the other two lifters you read about before. Since the lifter moves the length of the surface, the exceptionally slight grating is delivered; subsequently, the parts don't wear so a lot. As of not long ago, roller-type lifters were just utilized in elite applications. Regardless, in the present occasions, they are being utilized in standard traveler vehicles all the more oftentimes due to their better wear attributes. |

AuthorWrite something about yourself. No need to be fancy, just an overview. Archives

June 2022

Categories

All

|

RSS Feed

RSS Feed