|

In any framework, valves are an essential part that controls a liquid's pressing factor, flow rate, and heading. Pneumatically controlled valves direct the flow of pressurized air which is urgent to your framework's prosperity. Although the medium flowing through the framework is liquid (equivalent to pressure driven or measure water frameworks), how control is executed contrasts from numerous points of view than with a fluid.

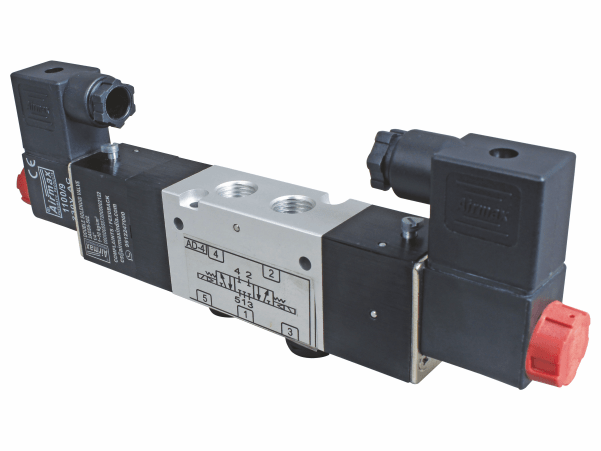

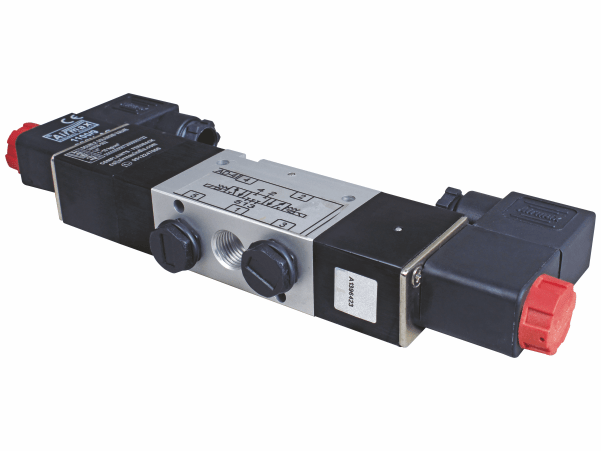

Flow Control and Directional Control Valves Valves that control flow are generally found in pneumatic frameworks. Flow control valves are accessible in two designs and are utilized in two distinct manners. The first is a variable limitation with a segment that opens or shuts the valve. This kind of valve could be known as a needle or a gag valve. The other kind is a check valve which permits flow one way, however limits flow the other way. Pneumatic frameworks can likewise highlight directional valves in numerous sizes, styles, or designs. These sorts of valves can fluctuate from a straightforward check valve to a more perplexing valve with changing positional envelopes and work ports in the valve. The directional valve includes an administrator which gives the power to move the valve between its positions. The administrator can be controlled by an assortment of instruments including a manual switch, electric solenoid, air pilot, cam system, or others. Different Considerations for Pneumatic Valves While pressure alleviation, flow control, and pneumatic directional control valve might be the most famous pneumatic valves, these valves can come in all sorts of assortments. Another regular pneumatic valve is a poppet valve that utilizes a spring to push the face of the poppet down on its seat. These valves regularly flow one way, like a check valve, however are invigorated to flow backward. Spool valves are another pneumatic valve you may go over in your inquiry. Spool valves have a scored metal chamber that slides inside a correctly machined body that is penetrated somewhere in the range of three to seven ports. At the point when you are picking your pneumatic valve, you will see that most directional valves come in both standard and non-standard mounting arrangements. The non-standard arrangement is developed at the idea of the maker. Port situating, administrator style, and mounting choices will be elite relying upon where the valve is from. Because of the irregularities among makers and their mounting inclinations, it is ideal to explore the item generally reasonable for your framework. Notwithstanding, there are additional lines of standardized valves that may suit at least one determination. In the event that your valve is specific to specific detail, it implies that one maker's valve will fit the subplate or complex of another manufacturer's. Also, port and electrical associations are standardized with most valves to help in your choice.

0 Comments

The rotary joints are a mix of fragments that get together to enable the turn of the combined parts. Such parts are habitually used as a contraption to make a seal between a fixed line or chamber that arrangements a segment, for instance, liquid, and a rotating portion which would, generally speaking, be as a drum, pivot, or other such turning chambers. These fixing sections, for instance, Airmax rotary joints license the movement of the gave media into and out of the rotating drum or another such turning archive. The media typically associated with these revolving affiliation devices join any similarity to water, warm oil, pressure-driven fluid, and a wide arrangement of engineered liquid coolants. Airmax Pneumatics is quite possibly the most experienced rotary joints manufacturer on the planet. They make their high type and trustworthy rotary joint things by wanting to consolidate what they depict as their standard core value of intensive customer-driven accommodation got together with a solid creative establishment reliant on the most awesome current and creating progress. Rotary Joint Temperature and Pressure Thresholds The rotary joints created by means of Airmax pneumatics are proposed to have the alternative to withstand phenomenal loads and either freezing or high temp water. These rotational affiliations will supervise steam temperatures up to 250 degrees Celsius (482 degrees Fahrenheit). In case the media being moved by methods for the rotating affiliations is hot oil, by then, the Airmax rotational joints can manage an extended temperature of up to 390 degrees Celsius (734 degrees Fahrenheit). The upper weight edge while moving water-driven oil is 350 bar, with the upper vaporous pressure limit set at 40 bar. Engineered coolants used with Airmax rotating joints have a weight breaking point of up to 150 bar. Employments of Rotary Joint Airmax rotary joints can be found in a wide variety of mechanical areas, for instance, in the machine gadget industry and the fields of material, plastic, and paper creation. Various endeavors using these Airmax pneumatics parts versatile collecting, food creation, similarly as the steel, manufactured, and energy organizations.

Did you realize that moisture is consistently present in the air, regardless of whether we can't see it? At the point when the air is compressed in a compressed air framework and is cooled past its dew point, it gathers into fluid water. This makes a problem, as compressed air frameworks depend on dry air and can't play out their capacities appropriately if the air is wet. All the more explicitly, the air should not contain any fluid moisture and ought to be at a general stickiness of under half to forestall erosion. Moisture in Compressed Air is Damaging Need to know precisely what inconveniences fluid water in air frameworks can cause? Look at the accompanying:

Eliminating moisture for consumption insurance is additionally significant for the gear utilizing the air and the air framework itself. Particulate made from rust and scale can foul lines and harm segments of the air framework. In the most pessimistic scenario, consumption could prompt disappointment in the line work, making spills and keeping air from arriving at the cycle where it is required. Most producers utilize compressed air dryers as one of the strategies for eliminating moisture. Air leaving a blower is warmed and 100% immersed with water. As the air cools, fluid water starts to gather. Since the air ordinarily gets cooler the further it gets into the framework (air frameworks likewise regularly go through chilly territories like the outside prior to arriving at the cycle), it is considerably more successful to dry the air before placing it into the air net. The air channels and moisture separator can eliminate moisture from the compressed air and to eliminate water fume, you should utilize a dryer. Eliminating Moisture from Compressed Air

There are few methods for eliminating moisture from compressed air:

|

AuthorWrite something about yourself. No need to be fancy, just an overview. Archives

June 2022

Categories

All

|

RSS Feed

RSS Feed