|

In any framework, valves are an essential part that controls a liquid's pressing factor, flow rate, and heading. Pneumatically controlled valves direct the flow of pressurized air which is urgent to your framework's prosperity. Although the medium flowing through the framework is liquid (equivalent to pressure driven or measure water frameworks), how control is executed contrasts from numerous points of view than with a fluid.

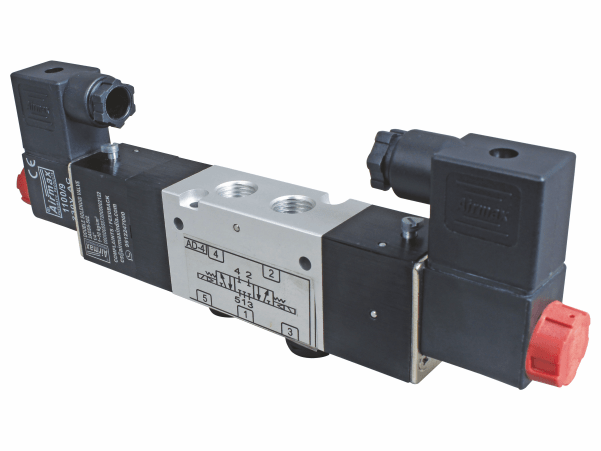

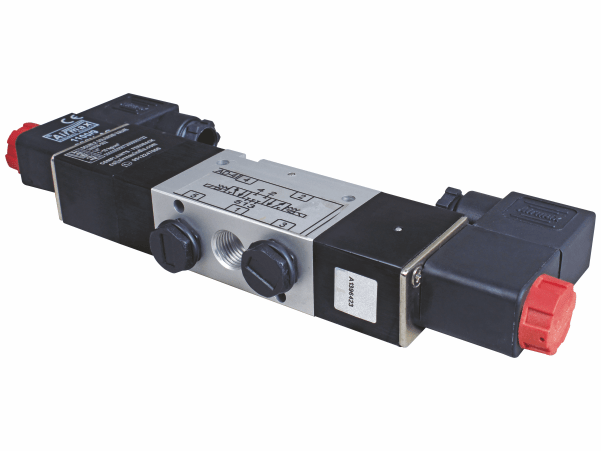

Flow Control and Directional Control Valves Valves that control flow are generally found in pneumatic frameworks. Flow control valves are accessible in two designs and are utilized in two distinct manners. The first is a variable limitation with a segment that opens or shuts the valve. This kind of valve could be known as a needle or a gag valve. The other kind is a check valve which permits flow one way, however limits flow the other way. Pneumatic frameworks can likewise highlight directional valves in numerous sizes, styles, or designs. These sorts of valves can fluctuate from a straightforward check valve to a more perplexing valve with changing positional envelopes and work ports in the valve. The directional valve includes an administrator which gives the power to move the valve between its positions. The administrator can be controlled by an assortment of instruments including a manual switch, electric solenoid, air pilot, cam system, or others. Different Considerations for Pneumatic Valves While pressure alleviation, flow control, and pneumatic directional control valve might be the most famous pneumatic valves, these valves can come in all sorts of assortments. Another regular pneumatic valve is a poppet valve that utilizes a spring to push the face of the poppet down on its seat. These valves regularly flow one way, like a check valve, however are invigorated to flow backward. Spool valves are another pneumatic valve you may go over in your inquiry. Spool valves have a scored metal chamber that slides inside a correctly machined body that is penetrated somewhere in the range of three to seven ports. At the point when you are picking your pneumatic valve, you will see that most directional valves come in both standard and non-standard mounting arrangements. The non-standard arrangement is developed at the idea of the maker. Port situating, administrator style, and mounting choices will be elite relying upon where the valve is from. Because of the irregularities among makers and their mounting inclinations, it is ideal to explore the item generally reasonable for your framework. Notwithstanding, there are additional lines of standardized valves that may suit at least one determination. In the event that your valve is specific to specific detail, it implies that one maker's valve will fit the subplate or complex of another manufacturer's. Also, port and electrical associations are standardized with most valves to help in your choice.

0 Comments

Leave a Reply. |

AuthorWrite something about yourself. No need to be fancy, just an overview. Archives

June 2022

Categories

All

|

RSS Feed

RSS Feed