|

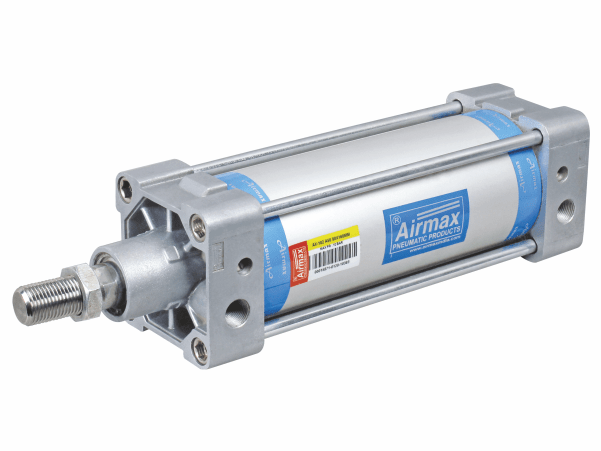

Pneumatic cylinders are the maximum frequent solution to create pressure and motion in OEM applications. The motives for this is that they may be easy in design, easy to put in, in your price range in charge, and sturdy in overall performance. Pneumatic cylinders are designed in a ramification of sizes, styles, and configurations. OEMs need to pick out the pneumatic cylinder carefully, so as to aid the application properly. The simplest way to gain that is to keep some tips in mind. The factors given underneath will help OEMs apprehend the components to recollect while deciding on pneumatic cylinders for their packages. In this submission, we can be looking at rod fashion cylinders. A round body pneumatic cylinder can be designed in two approaches – single, or double appearing. Single acting cylinders deliver compressed air to the handiest one aspect of the piston, consequently developing force and motion most effectively in one route. Double performing cylinders deliver compressed air to create sufficient force to extend in addition to retract strokes. Single performing cylinders have restricted extension due to the presence of a compressed spring within the design. The stroke period for double performing cylinders is unlimited, however the piston rod can bend or buckle after regular use over a time frame.

Pneumatic cylinder air consumption takes region due to elements. The first is the quantity of air that the piston displaces at some point of operation. The second is infected air extent that passes via the valves, ports, tubing, and end cover cavities. Customers must test whether the cylinder can supply air even in worst case situations. If the pneumatic cylinder is capable of meeting all of those criteria, then you could be certain that the cylinder will carry out well for your OEM utility.

0 Comments

Leave a Reply. |

AuthorWrite something about yourself. No need to be fancy, just an overview. Archives

June 2022

Categories

All

|

RSS Feed

RSS Feed