|

A rotary joint, moreover insinuated as a rotary affiliation or rotating affiliation, is a rotary fixing contraption that interfaces going equipment to fixed channeling for the trading of steam, water, warm oil, coolant, pressure driven oil, air, and other media. Rotary affiliations can be arranged with various sections and manage different media types meanwhile. In these cases, a fragile seal, for instance, an O-ring is used to keep the fluids from "navigate" into another section. Fragile seal multi-passage rotary affiliations are used in a combination of adventures and applications including oil and gas, food and drink, aeronautics, apply self-rule, and clinical contraptions. In specific applications, the rotary affiliation is fitted with slip rings for imparting electrical signals similarly as water driven power. With standard rotary joints, a spring-stacked seal is used to keep the fluid or gas medium from being dispersed into the environment. The spring is used in the rotary joint to keep up the basic inside seating, and the rotary joint is pressure-fixed once in movement. Low-weight or vacuum organization relies upon the spring ability to make the seal. Customary rotary joints are either self-reinforced with the usage of an inside carbon control, or external maintained using bars or a mounting segment. The seals are the essential wearing portions of a rotary union and rotary affiliation. During movement, seals can experience internal stacking powers from fluid weight, similarly as disintegration from contact between the fixing faces. Factors related to the machine speed, temperature, and media used can moreover impact the existence of the seal ring. To an immense degree, a rotary affiliation is simply on a standard with its seal pack. Bad quality seals ordinarily obliterate even more rapidly, provoking a development in upkeep, individual time, and fix cost. Right when a seal crashes and burns, media move away and the viability of the entire warming or cooling measure perseveres. The aggregate of this makes the genuine replacement cost of the seal just a little piece of the total cost of a seal frustration.

Airmax Pneumatics is outstanding amongst other Rotary Joint Manufacturer in India. They are fabricating their items from top notch materials. They trade items to Gulf nations just as to Bangladesh and to approach by nations.

0 Comments

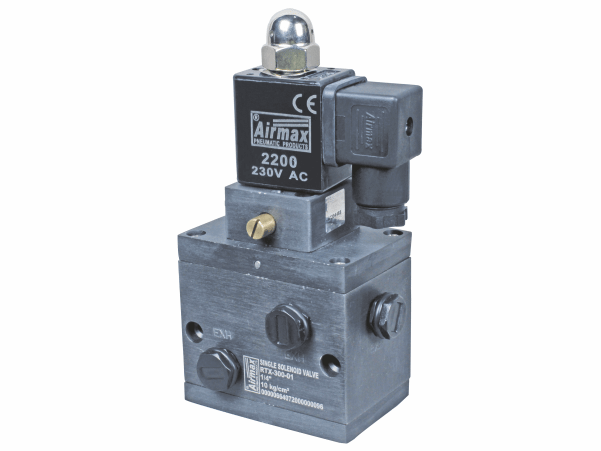

The poppet solenoid valve utilizes an Associate in Nursing passage cowl that is order found by a spring or the major problem of the medium chasing through the valve. The magnet changes matters of the poppet valve either soundly or by the usage of a pilot (depicted underneath), that opens or closes the part. poppet valves contemplate higher stream rates by and by initiation force of the magnet should be passed in spool valves to oblige for the squeezing factors following educated the poppet valve. 2, 3, or four strategies Valve work

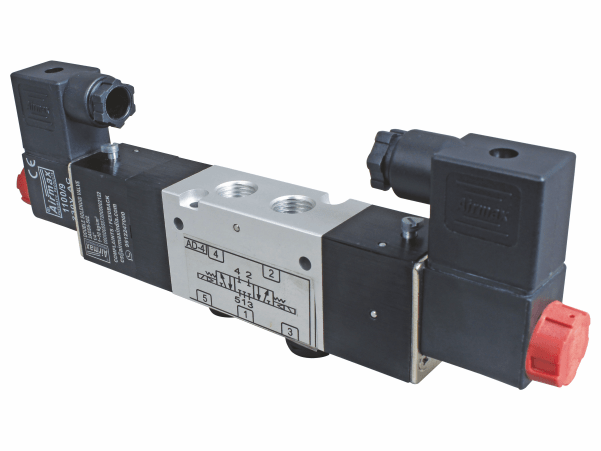

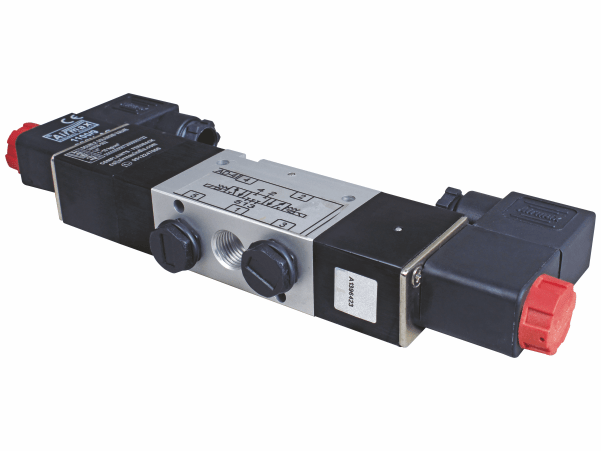

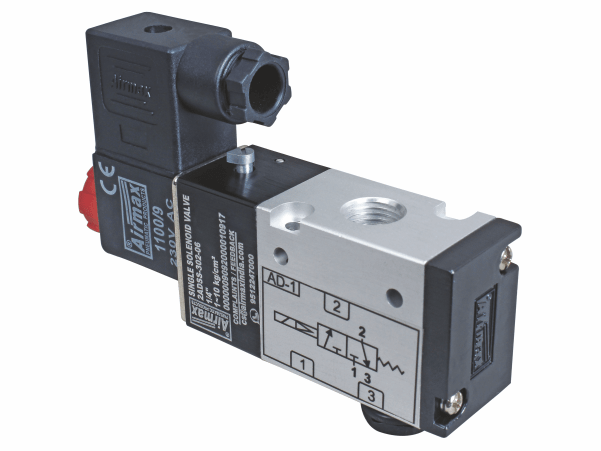

2 Way Stream rate is stressed by a valve between the bay and outlet port. 3 Way Most three strategy valves use one port as a bay and a couple of as retailers. The magnet is utilized to control the narrows stream to the ideal outlet port. three strategy valves will in like manner use 2 ports as bays Associate in Nursingd a lone port as an outlet, to acknowledge blending limits. 4 Way A four way valve has four or five ports. there's one bay, two|and a couple of|and a couple of} outlet ports comparative as a three way valve however whichever outlet port is off transformed into an Associate in Nursing helper channel port that courses the stream to the last one or 2 exhaust ports. pretty much four strategy valves to boot have three techniques arranging. rather than choosing between 2 manners by which of development (2 ways arranging) as incontestible inside the chart to a lower place, the magnet is to boot prepared for a third position that hinders all fluid from taking off through the valve to remain up the major problem corporate leader keen. Pilot The pilot worked magnet valves have a poppet valve or mid-region that is order closed by a spring and hence the differential major problem between the delta and outlet ports. A reduced assistant channel interfaces the inlet and outlet ports on one or the contrary feature of the poppet valve. The magnet controls travel through this non required channel, and once it's inside the open state it allows a limited measure of the medium to stream to the capacity supply port that begins to try and out the major problem following educated the poppet valve till it opens and mulls over the full stream. Pilot valves are extra delayed than direct-acting valves yet take into thought a decreased magnet to control higher stream. Every now and again Open or typically Closed While authentic interaction the ability of the magnet valves, common implies the unpowered state. Actuating the magnet can make the converse state. In things any place magnet work is relative, the change in states may happen in degrees. Solenoid valves provide pragmatic strategies for electronic management for the progression of fluids and gases. With water-driven and gas applications unfold during ventures from automotive to food administration, these gadgets assume a large half in current mechanics. To additional promptly comprehend their capability and verbiage, we've opened up some of the essential ideas in plain terms.

1. frequently Open or usually Closed While representational process the capability of the magnet valves, typical alludes to the unpowered state. Inciting the magnet can create the reverse state. In things wherever magnet work is relative, the adjustment in states might occur in degrees. 2. poppet valve or Spool

Poppet Poppet type solenoid valve use Associate in Nursing entry cowl that is command discovered by a spring or the pressing issue of the medium hunting through the valve. The magnet changes matters of the poppet valve either squarely or by utilization of a pilot (portrayed beneath), that opens or shuts the section. poppet valves take under consideration higher stream rates nevertheless activation power of the magnet ought to be beyond in spool valves to oblige for the pressing factors following informed the poppet valve. Spool Spool sort valves have seals on the drag of the spool. because the magnet impacts matters of the spool, the arrangements of the seals modification to prevent or allow stream. Spool sort valves have less surface zone that's wedged by the pressing issue of the stream, in order that they are incited utilizing less ground-breaking solenoids. The drawback is that they likewise have an additional restricted stream rate. 3. Direct or Pilot Direct Direct-acting solenoids impact the progression of the medium by squarely modifying matters of the poppet valve or spool to open or shut the valve. Direct-acting valves are fast and have less complicated arrange standards but are less slot in high stream applications. Pilot The pilot worked magnet valves have a poppet valve or abdomen that's command shut by a spring and therefore the differential pressing issue between the delta and outlet ports. A diminished auxiliary channel connects the gulf and outlet ports on one or the opposite facet of the poppet valve. The magnet controls move through this non mandatory channel, and once it's within the open state it permits a restricted amount of the medium to stream to the ability supply port that starts to even out the pressing issue following informed the poppet valve till it opens and takes under consideration full stream. Pilot valves ar additional slow than direct-acting valves but take into thought a diminished magnet to regulate higher stream. 4. 2, 3, or four methods Valve operate 2 Way Stream rate is strained by a valve between the gulf and outlet port. 3 Way Most three method valves utilize one port as a gulf and a pair of as retailers. The magnet is employed to guide the bay stream to the perfect outlet port. three method valves will likewise utilize 2 ports as gulfs Associate in Nursingd a solitary port as an outlet, to realize mixing capacities. 4 Way A four method valve has four or five ports. there's one gulf, two|and a couple of|and a pair of} outlet ports similar as a three method valve but whichever outlet port is off turned into an Associate in Nursing auxiliary channel port that courses the stream to the last one or 2 fumes ports. just about four method valves to boot have three methods situating. instead of selecting between 2 ways in which of movement (2 paths situating) as incontestible within the graph to a lower place, the magnet is to boot equipped for a 3rd position that obstructs all liquid from heading out through the valve to stay up the pressing issue corporate executive savvy. Pneumatic cylinders can be found in thousands of different kinds and have a great number of uses in automation. When choosing the ideal sort of air compressor which can work in a particular program, it's ideal to consider particular design guidelines and essential elements affecting that particular function. There are six vital elements to your cylinder designed with excellence. Each of these must be well thought to ensure the fantastic functioning of the electrical system. Air Flow Requirements: The air supply to your pneumatic cylinder is essential to its proper function as it is the atmosphere that becomes compacted sufficiently to execute the mechanical function generated by the cylinder. Determining airflow demands is different for single-acting cylinders and double-acting cylinders. For the air compressor to operate well and create the greatest possible compression of between seven to 10 pubs, both the compressor, air tank, and also pipe must be well assembled. Piping at a Pneumatic Cylinder: When air flows through a pipe or tube, the pressure is lost due to the flow friction that's created along with other corrosive losses and resistances. This vitality is represented as an anxiety loss. Reducing the reduction of pressure in pneumatic circuits is vital to the overall effectiveness of this system. To realize that the real significance of maximum compression with minimal pressure reduction, pipes and tubes must be carefully linked and be kept clean. Air leakage cannot be avoided and air quality needs to be guarded via using adequate filtration. Lubricants are necessary for the fantastic performance of a pneumatic cylinder. Pneumatic tools used in extreme hot or cold temperatures may necessitate air conditioners and other devices to avoid freezing. Lubrication reduces wear and prolongs the life of the cylinder, preventing flaking and rust sludge seen in compressed air systems.

Pneumatic Circuits: A deep understanding of the connection between loading variables and the overall performance of a pneumatic tube is crucial when designing a pneumatic circuit breaker. Each component must be well constructed and fit especially to the desirable performance demanded of it inside the circuit. Cost efficacy and fail-safes give rise to the excellence of this circuit, reducing harm during the performance. The Solenoid Valve: Solenoid valves are commonly used because this kind of valve is reliable and popular in most applications. Adding compressed air to apparatus in a circuit, this kind of valve enables large devices to be controlled with little signals and provides an interface between electronics controllers. Solenoid valves need to be made from the best materials since they defy a whole lot of pressure. Last Notes on Safety: Deciding upon a company with a high standard of excellence in the production of pneumatic cylinders is important for the smooth functioning of a circuit. The components of electrical cylinders all provide real value to this system and every part must be well considered in the selection, installation, and maintenance of a pneumatic system. In any framework, valves are an essential part that controls a liquid's pressing factor, flow rate, and heading. Pneumatically controlled valves direct the flow of pressurized air which is urgent to your framework's prosperity. Although the medium flowing through the framework is liquid (equivalent to pressure driven or measure water frameworks), how control is executed contrasts from numerous points of view than with a fluid.

Flow Control and Directional Control Valves Valves that control flow are generally found in pneumatic frameworks. Flow control valves are accessible in two designs and are utilized in two distinct manners. The first is a variable limitation with a segment that opens or shuts the valve. This kind of valve could be known as a needle or a gag valve. The other kind is a check valve which permits flow one way, however limits flow the other way. Pneumatic frameworks can likewise highlight directional valves in numerous sizes, styles, or designs. These sorts of valves can fluctuate from a straightforward check valve to a more perplexing valve with changing positional envelopes and work ports in the valve. The directional valve includes an administrator which gives the power to move the valve between its positions. The administrator can be controlled by an assortment of instruments including a manual switch, electric solenoid, air pilot, cam system, or others. Different Considerations for Pneumatic Valves While pressure alleviation, flow control, and pneumatic directional control valve might be the most famous pneumatic valves, these valves can come in all sorts of assortments. Another regular pneumatic valve is a poppet valve that utilizes a spring to push the face of the poppet down on its seat. These valves regularly flow one way, like a check valve, however are invigorated to flow backward. Spool valves are another pneumatic valve you may go over in your inquiry. Spool valves have a scored metal chamber that slides inside a correctly machined body that is penetrated somewhere in the range of three to seven ports. At the point when you are picking your pneumatic valve, you will see that most directional valves come in both standard and non-standard mounting arrangements. The non-standard arrangement is developed at the idea of the maker. Port situating, administrator style, and mounting choices will be elite relying upon where the valve is from. Because of the irregularities among makers and their mounting inclinations, it is ideal to explore the item generally reasonable for your framework. Notwithstanding, there are additional lines of standardized valves that may suit at least one determination. In the event that your valve is specific to specific detail, it implies that one maker's valve will fit the subplate or complex of another manufacturer's. Also, port and electrical associations are standardized with most valves to help in your choice. The rotary joints are a mix of fragments that get together to enable the turn of the combined parts. Such parts are habitually used as a contraption to make a seal between a fixed line or chamber that arrangements a segment, for instance, liquid, and a rotating portion which would, generally speaking, be as a drum, pivot, or other such turning chambers. These fixing sections, for instance, Airmax rotary joints license the movement of the gave media into and out of the rotating drum or another such turning archive. The media typically associated with these revolving affiliation devices join any similarity to water, warm oil, pressure-driven fluid, and a wide arrangement of engineered liquid coolants. Airmax Pneumatics is quite possibly the most experienced rotary joints manufacturer on the planet. They make their high type and trustworthy rotary joint things by wanting to consolidate what they depict as their standard core value of intensive customer-driven accommodation got together with a solid creative establishment reliant on the most awesome current and creating progress. Rotary Joint Temperature and Pressure Thresholds The rotary joints created by means of Airmax pneumatics are proposed to have the alternative to withstand phenomenal loads and either freezing or high temp water. These rotational affiliations will supervise steam temperatures up to 250 degrees Celsius (482 degrees Fahrenheit). In case the media being moved by methods for the rotating affiliations is hot oil, by then, the Airmax rotational joints can manage an extended temperature of up to 390 degrees Celsius (734 degrees Fahrenheit). The upper weight edge while moving water-driven oil is 350 bar, with the upper vaporous pressure limit set at 40 bar. Engineered coolants used with Airmax rotating joints have a weight breaking point of up to 150 bar. Employments of Rotary Joint Airmax rotary joints can be found in a wide variety of mechanical areas, for instance, in the machine gadget industry and the fields of material, plastic, and paper creation. Various endeavors using these Airmax pneumatics parts versatile collecting, food creation, similarly as the steel, manufactured, and energy organizations.

Did you realize that moisture is consistently present in the air, regardless of whether we can't see it? At the point when the air is compressed in a compressed air framework and is cooled past its dew point, it gathers into fluid water. This makes a problem, as compressed air frameworks depend on dry air and can't play out their capacities appropriately if the air is wet. All the more explicitly, the air should not contain any fluid moisture and ought to be at a general stickiness of under half to forestall erosion. Moisture in Compressed Air is Damaging Need to know precisely what inconveniences fluid water in air frameworks can cause? Look at the accompanying:

Eliminating moisture for consumption insurance is additionally significant for the gear utilizing the air and the air framework itself. Particulate made from rust and scale can foul lines and harm segments of the air framework. In the most pessimistic scenario, consumption could prompt disappointment in the line work, making spills and keeping air from arriving at the cycle where it is required. Most producers utilize compressed air dryers as one of the strategies for eliminating moisture. Air leaving a blower is warmed and 100% immersed with water. As the air cools, fluid water starts to gather. Since the air ordinarily gets cooler the further it gets into the framework (air frameworks likewise regularly go through chilly territories like the outside prior to arriving at the cycle), it is considerably more successful to dry the air before placing it into the air net. The air channels and moisture separator can eliminate moisture from the compressed air and to eliminate water fume, you should utilize a dryer. Eliminating Moisture from Compressed Air

There are few methods for eliminating moisture from compressed air:

Smooth and present-day espresso machines have new and valuable gadgets for filtering the water. The water solenoid assumes a high significance job in the espresso machine for its sanitizing choice. The new espresso machines with water solenoid valve packs have these key highlights: They naturally administer up to 320 cups, sugar, and cold beverages in glass jugs and tidbits (chocolates, chips, and so forth) or portions. It additionally accompanies a coffee great form of coffee, upkeep, and simple cleaning. These water solenoid valve espresso machines uphold the most utilized equal and sequential MDB's BDV and Executive installment frameworks. Its highlights incorporate standard full-range CPU, adaptable settings, redoing and designing plate and twistings and furthermore wellbeing and security include for both the client and administrator. Specialized Specifications for a water solenoid based espresso machine:

A single solenoid valve manufacturer and a single installment framework for conveying hot and cold drinks, painted steel sheet lodging, extended polystyrene protection, treated glass with two layers of protection, Slot item appropriation: flat turn furnished with hostile to robbery framework, Containers, and tanks in contact with food-grade gum affirmed, portable plastic plate, which gives protection from the weight. The situation of the plate can be effectively be changed. Sugar and water, espresso and cups, spoons. The arrangement of the machine can design itself naturally and reset each time the gadget fizzles. You can program your temperature and furthermore the selling costs (up to 25 selling costs) It likewise has an electronically controlled heater temperature, and interior dampness gatherer, and extra authority steam in the item circulation. It has fluorescent cylinder lighting, electromagnetic vibration siphon for the coffee variant. Outfitted with an enemy of ice sensor: programmed cycle defrost and hostile to flood. Reset the basic instance of blunders and cause a program to restart the machine. It has an evaporator wellbeing valve, security transfers for 24 V parts, wellbeing warm voltage line fueled gadgets, security indoor regulator, and against bubbling moment items for the moment form. Physically utilization of the water solenoid pack and water purifier unit, CE, VDE, and UL for the coffee variant. The industrial revolution ushered in an entire new level of sector, where society has increasingly relied on innovative technology and machines to fuel economic growth and enable us to live at a level of relaxation that is unprecedented. In order to run the advanced machinery, complex processes such as radioactivity, high pressure and temperature control are required. Luckily, we have machines that can perform these sorts of tasks reliably and safely. One of the mainstays in industrial procedures are valves. They are used to control temperature, pressure, capacity and also the flow of liquids in machinery and industrial processes. Among the most useful types are solenoid valves. There is also a single solenoid valve and double solenoid valves are available. Solenoid valves make usage of electricity to control the speed and rate of fluids in a variety of types of systems and machines. Electric energy flows into a solenoid coil which leads to the creation of a magnetic field that opens a plunger to allow gas and other liquids to flow through.

Solenoids are employed in several different industries and a wide collection of processes and machines. They're employed in terminals in addition to rotary applications to control fluid power motors, cylinders and other kinds of industrial processes. Some of the major industries which use solenoids incorporate the dental health, appliance, energy, medical and transportation industries. Linear programs incorporate the use of solenoids in brakes, vending machines, door locks, copiers, coin changers, pumps, disk drive locks, film processors and electric typewriters. Rotary solenoid applications include circuit breakers, counters, defibrillators, machine tools, and textile machines. In dentist chairs they control both air and water flow. To put it differently, solenoids are part of our daily life without us even knowing it. The use of solenoids are really beneficial in a vast array of machines and industries due to their reliability, cost effectiveness and durability. There are also a number of different kinds of solenoid valves to fulfill various specific needs of industry. Solenoid valves are direct-acting or pilot-operated valves. They also come with two or more ports. Direct-acting solenoid valves are most frequently used for controlling low volume valves. This is because they contain just one electromagnetically control set. Pilot-operated valves are included in a blend of valves, which makes it possible to use them in higher volume applications. The use of solenoids offers several important benefits, especially compared with other kinds of pneumatic and hydraulic layouts. Solenoids typically operate faster and tend to be a lot easier to install in addition to maintain. Generally, solenoids also offer more constant workforce during a lengthy time period. They also offer you dependable performance. In summary, solenoids offer the advantages of longevity, reliability, speed and ease of installation and maintenance compared to other types of industrial designs. They also tend to be very reasonably priced. Solenoids are part of our daily life without us even realizing it. The simplicity of the design actually contributes to a lot of vital aspects of our lives, from the dishes we wash, java we brew and we use in our automobiles. Whether we are seeing the dentist turning to our automated sprinkler system, there is a fantastic opportunity that solenoids are operating behind the scenes to ensure the correct and safe flow of gas, water or other fluids from the machines and systems we use every day. A pneumatic cylinder is a gadget that has been precisely designed to create power (in straight movement) from packed gas. They are otherwise called air cylinders.

The air cylinder manufacturer has offer different appearances and estimates and is intended to perform various capacities relying upon the rising necessities of the market. Contingent upon your prepared market, you can decide to go for 1) Single-acting Cylinder This kind of air cylinder is tiny in size when contrasted with different sorts. They make driving direct power (decisively &lout') from the weight granted by the packed air by the cylinder which at that point springs back to the first position. This kind of air cylinder will be the best reason for the clients who need little application since it has a restricted expansion because of the little space for compacted air. 2) Double acting cylinders With the extended application, a client can think about purchasing this machine. It has two ports that empower it to perform both expand and withdraw strokes. Its stroke length is additionally not restricted a reality that presents the double-acting cylinder a superior decision of pneumatic cylinder that ought to never miss in your handyman store stock. 3) Multiple stage telescoping cylinder As the name recommends, it is a mix of both single-acting cylinder and the double-acting cylinder in execution ability. With both cylinder bar settled with an arrangement of empty stages in expanding distances across; this machine permits striking longer strokes. lt is the best device for clients who manage applications that have insignificant side loading. These are the primary sorts of air cylinders that are notable and generally utilized whose requests suit the market. In any case, there are different sorts too. Why would it be advisable for you to stock the pneumatic cylinders? The air cylinders work with the fundamental material science standards which express that power created by the cylinder is straightforwardly corresponding to the surface zone of the cylinder acting on it with different components like the grinding and the choppiness kept consistent. This hypothetically infers that the machine performs dependably somewhere in the range of half and 70%. Their broad utilization makes them more attractive. Numerous specialists decide to utilize the pneumatic cylinder since they are cleaner, produce less noise, and needn't bother with huge space for liquid storage. What's more, pneumatic cylinders are likewise the most favored in the market since their working liquid is a gas; by the way that gases don't trickle during spillages keeps the working climate cleaner. The air cylinders are additionally commendable in the stock since their decision of utilization is more extensive relying upon the employment detail, the degree of burdens, temperature, and stroke length required. Air cylinder introduced with fast fumes valves builds the air cylinder cycle. This makes your stock more attractive and permits snappy recharging of stock as these will be the most favored machines. When going to search for the pneumatic cylinders, the client is frequently determined by the nature of the item. As a business person of air cylinders, you need to win the trust of your client by loading standard air cylinders that have a wide scope of bone sizes of 16 and 18 crawls of bore sizes and metric sizes separately. The cylinders should likewise have many mounting setups and standard switch ability that depends on the area of the application and match-failure of the air cylinder. For the double-acting pneumatic cylinders with two weight arrangement, you can consider loading the sorts with air weight and fumes valve introduced which during activity prompts a higher weight creation for the work power and low weight for bringing power back. This adjustment deliberately diminishes the operational cost; includes that have made air cylinders more attractive as such are the machines that can be multipurpose. While working with the pneumatic cylinder, clients are frequently pissed up by the clamor it produces from the impacting air cylinder end covers. The commotion isn't simply disturbing to the client yet in addition hurtful to the machine itself and this could be a side road to the administrators. Thusly to make little yet huge changes to your models in stock will be for your business' potential benefit. You can either add to your stock the inward pads or modify your machines by fixing the pads that will add to the stroke time and decrease commotion delivered by the loaded air cylinders. Pads are consistently movable henceforth are more affordable. This will essentially expand the interest from your clients just as making the air cylinder more appropriate for utilizing even to clients in commotion limited zones. In your stocking, you can likewise consider having a constant input sensor and shut circle valve regulator fused air cylinders in stock consequently making them both completely expanded and completely withdrawn. These machines will viably give straight electric drives a quality searched for on the lookout. The highlights air cylinders certainly present uniqueness an expanded interest for your fed machines that will make them exceptionally serious on the lookout. Why the pneumatic cylinder suits a more extensive market The changed sizes of the device with the capacity to perform different positions that shift from picking exceptionally little items to bigger ones make them more appropriate for modern utilize generally in various fields. You will never again endure a dead-stock with these sorts of adaptable air cylinders since they permit the administrator to have full authority over it as it follows an instructed movement or list to different movable areas of the administrator's decision. ln expansion to that, the plan of air cylinder suits the huge requirements of your clients regarding setup and extent of use. Thusly, your customers will easily offer to get a specific incentive for their cash. The sturdiness of a machine is likewise one of the main impetus to numerous clients and having air cylinder stock with order start and stop purposes of movement not exactly the full stroke of a cylinder makes the pneumatic cylinders more strong. With these highlights, alterations and expansive use of pneumatic cylinders straightforwardly convert into their interest in the market with guaranteed moving-stock. |

AuthorWrite something about yourself. No need to be fancy, just an overview. Archives

June 2022

Categories

All

|

RSS Feed

RSS Feed